Medical Catheter Mandrels – How to Choose the Right Type and Get the Best Results in Production

If you’ve ever worked on high-precision medical catheters, you know the importance of controlling every millimeter of the product’s shape. The mandrel—the slender rod or tube inserted into the catheter during manufacturing—might not look like much, but it’s what defines the lumen’s diameter, keeps the shape stable, and ensures the inner surface is as smooth as it should be, which is crucial for devices like Hypodermic Needles, Spinal Needles, or Tuohy Epidural Needle that demand precise lumen dimensions.

Get the mandrel wrong, and you could be facing lumen distortion, sticky demolding, or inconsistent performance. Get it right, and you’ll have smooth production, fewer rejects, and catheters that perform as intended.

Therefore, in this guide, we’ll walk through six common mandrel types, how they’re used in catheter manufacturing, and what you should watch for when working with each one.

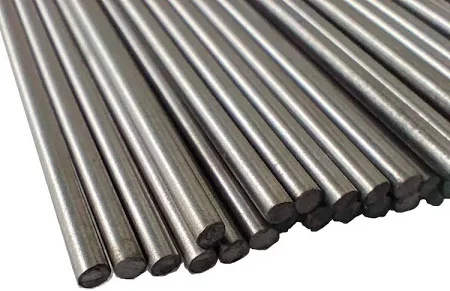

In many catheter production lines, stainless steel is the go-to mandrel material. Grades like 304 and 316 are popular for their corrosion resistance, affordability, and reliability. They come in solid rods, hollow tubes, and even thin-wall hypotubes for delicate multi-lumen designs, such as Laser Cut Hypotube used in minimally invasive tools like Endoscopic Biopsy Needles and Trocar Needles.

The main draw here is strength—stainless steel mandrels don’t flex much, so they hold your lumen shape firmly. When they’re precision-polished, the surface becomes slick enough to slide out of the catheter with minimal friction, making demolding fast and clean.

That said, stainless steel needs care: dents or scratches can leave marks on your catheter’s inner wall. Regular cleaning and occasional polishing keep the surface in top shape, and a simple roll-test on a flat table will reveal if a mandrel’s bent and needs straightening or replacing.

When you need a mandrel to follow extreme curves or survive repeated bending without permanent deformation, Nitinol steps in. Its superelastic properties mean you can form catheters with complex geometries—like helical tips or varying lumen paths—without fighting the tool.

Nitinol mandrels are especially valued in making sheaths for Nitinol guidewires or other flexible devices, including steerable systems for Meniscal Repair Needles, Nerve Block Needles, and Radiofrequency Needles where repeated flexing without deformation is essential.

But they’re more sensitive to surface damage: a small scratch can turn into a weak spot under repeated use.

If you’re running Nitinol in production, you’ll want to clean them promptly after forming to release any residual stress, and periodically check their recovery performance to make sure the superelasticity hasn’t degraded.

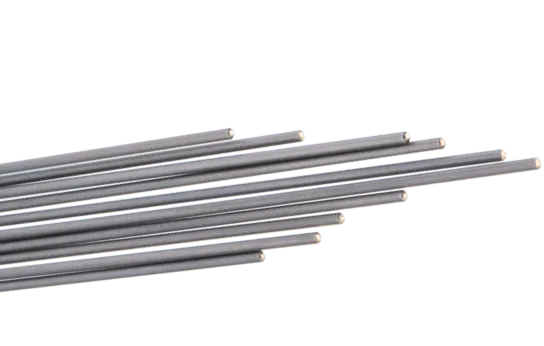

In certain catheter lines—especially reel-to-reel setups—the challenge isn’t strength, it’s minimizing drag. That’s where silver-plated copper wire mandrels shine. The copper core bends easily through complex lumen paths, while the silver plating keeps friction so low that even stubborn materials release cleanly.

These are often used for high-volume runs, where any delay in demolding can slow the whole line. This is particularly useful for fine-lumen products like Micro Needles, Bloodletting Needles, and Chiba Needles.

But the plating needs to stay intact—once it’s scratched or worn, friction rises fast. Many manufacturers treat these as single-use tools, so if you plan on using them repeatedly, handle them carefully during clamping and cleaning.

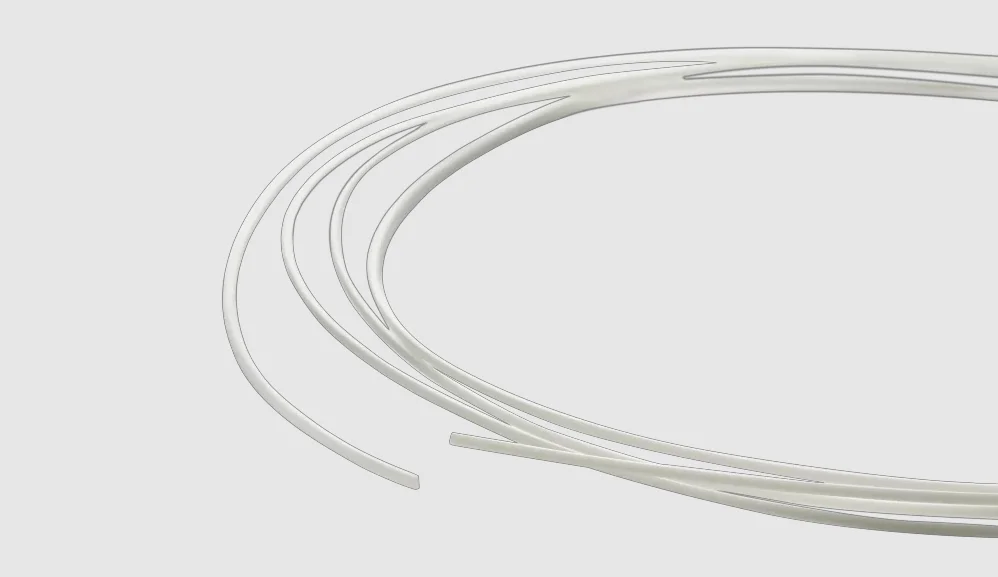

Some catheter applications involve aggressive drugs or solvents that would attack metals or other plastics. In those cases, PTFE (polytetrafluoroethylene) mandrels are the safe choice. They’re chemically inert, can take extreme hot and cold, and have a naturally slippery surface that makes demolding effortless.

That makes them ideal for catheters used in specialized tools like Echogenic Needles, PTC Needles, and Vacuum-Assisted Breast Biopsy Needles, where both chemical compatibility and smooth lumen finish are critical.

They’re available as rods or tubes, and you’ll see them a lot in catheters made for drug delivery or fluid handling. The main thing to watch out for is deformation—PTFE is softer than metal, so coiled stock needs to be straightened with gentle heat and tension before use, and sharp tools should be kept well away from the surface.

Polyoxymethylene (POM), sometimes called acetal, sits between metal and softer plastics in terms of strength. It’s rigid enough to hold shape during forming, but has a bit of give, making it forgiving to work with.

Polyoxymethylene (POM), sometimes called acetal, sits between metal and softer plastics in terms of strength. It’s rigid enough to hold shape during forming, but has a bit of give, making it forgiving to work with.

That balance makes POM mandrels a good fit for R&D environments or small-batch runs, especially when prototyping unique surgical tools such as Laparoscopy Shaver Blades, Arthroscopy Tube, or Orthopedic Shaver Blades.

They resist wear and keep dimensions stable, but they do have one weakness—UV light. Store them away from sunlight, and they’ll last much longer.

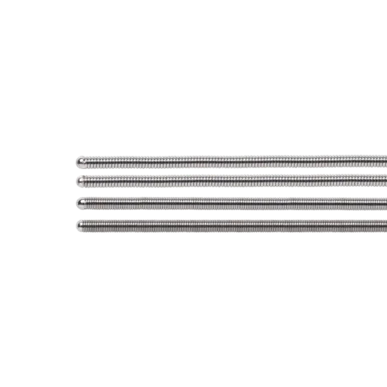

If you need the rigidity of stainless steel but the slick surface of PTFE, coating the metal core is the answer. A thin PTFE layer, often just a few microns thick, dramatically reduces friction, letting you form and demold without adding a liner to the catheter.

This is beneficial for smooth removal in products like Disposable Trocar, Visual Obturator Tubes, or Robotic Surgical Forceps Jaw.

The uncoated gripping zones mean you can handle them without damaging the coating, but you’ll still need to be gentle during cleaning. Avoid high-heat processes if your catheter also has a PTFE liner, since PTFE-to-PTFE contact at high temperature can cause sticking.

The design: number of lumens, complexity of the shape, wall thickness (e.g., single-lumen for OPU Needle, multi-lumen for Brachytherapy Needles or Soft Tissue Biopsy Needle)

The forming process: extrusion, reflow, or continuous production

Regulatory needs: chemical compatibility, mechanical strength, biocompatibility

Cost vs. life cycle: how many uses you’ll get before replacement

Inspect regularly for bends, scratches, or coating wear—especially when producing precision devices like H2O2 Transfer Needle, V3 Infusion Needle, or Veress Needles

Keep surfaces clean and polished

Store them properly—flat for rods, on large-radius spools for coiled stock

Track usage cycles to spot tools nearing the end of their service life

The mandrel might never appear in your finished product, but it shapes every catheter you make. Understanding the strengths and limits of each type—and caring for them properly—means smoother production, fewer rejects, and devices you can trust in the field.

At Shenzhen Manners Technology Co., Ltd., we bring precision engineering and medical manufacturing expertise together. As an ISO/TS certified company in Shenzhen, China, we specialize in human medical products, including stainless steel and Nitinol mandrels, needle manufacturing, laser cut tubing, five-axis machining blades, and medical-grade visible trocars. Beyond production, our team supports you with design assistance, R&D, rapid prototyping, and full project management. If you’re looking for a professional manufacturing partner who understands catheter production from the inside out, we’re ready to work with you—contact us today to discuss your needs.